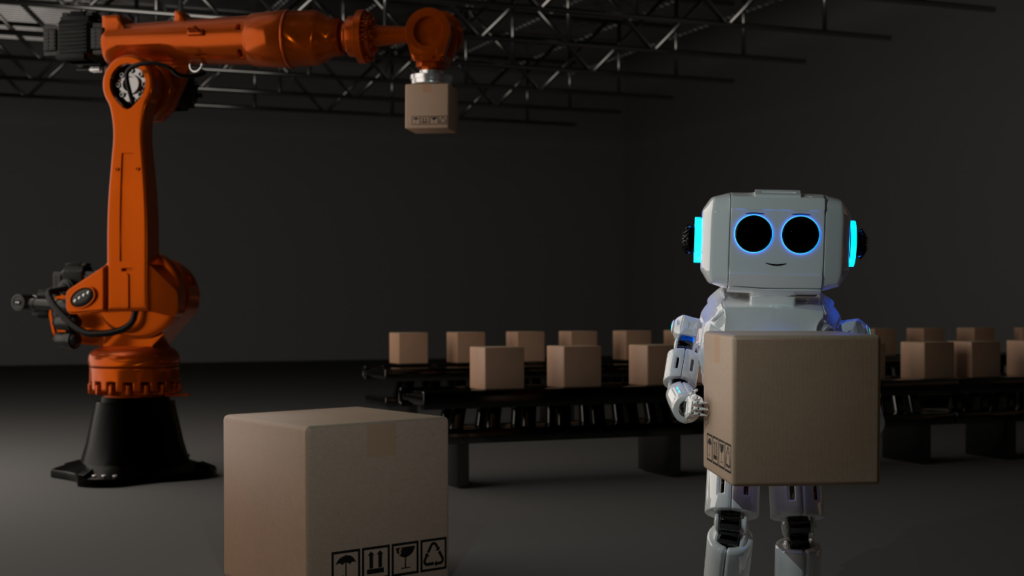

Overview of Automation in the Workplace

Automation is revolutionizing various workplace aspects. From manufacturing to services, robots and AI systems are taking over routine tasks and enhancing productivity. In manufacturing, for example, robots handle assembly lines, improving precision and efficiency. Service industries like retail and customer support also benefit from automation through chatbots and automated checkout systems.

Key Areas of Automation

- Manufacturing: Automation in manufacturing includes robots that assemble products, perform quality control, and manage inventory. Robotics streamline operations and reduce human error.

- Service Industry: In retail, self-checkout kiosks speed up the purchasing process. Customer service integrates chatbots to handle inquiries, improving response times and customer satisfaction.

- Healthcare: Automation aids in scheduling, patient management, and diagnostics. Robotic systems assist in surgery, increasing precision and reducing recovery times.

- Transportation: Self-driving vehicles and drones optimize logistics and delivery services. These technologies reduce costs and improve reliability.

Benefits of Automation

- Increased Efficiency: Automated systems work faster and more reliably than humans. Companies cut operation times and costs through automation.

- Higher Precision: Robots perform tasks with greater accuracy than humans, especially in repetitive tasks like assembly or diagnostics.

- Cost Savings: Initial investment in automation may be high, but reduced labor costs and increased productivity offer long-term savings.

- Safety Improvements: Robots handle dangerous tasks, reducing workplace injuries. In construction and manufacturing, automation ensures safer environments for workers.

Challenges and Concerns

- Job Displacement: Automation can replace many jobs, raising concerns about unemployment. Workers in repetitive roles face higher risks of displacement.

- Skill Gaps: As automation advances, demand for skilled workers increases. Employees need training in new technologies to stay relevant.

- Implementation Costs: High costs may hinder small businesses from adopting automation, impacting their competitiveness.

Automation’s impact on the workplace is significant and multifaceted. Understanding these dynamics helps us better prepare for the evolving job market.

The Evolution of Robotics in Various Industries

Robots transform industries by streamlining operations and enhancing productivity. Automation evolves to meet specific industry needs, each sector harnessing robotics uniquely.

Manufacturing and Production

Manufacturing leverages robotics for precision, efficiency, and consistency. Robots on assembly lines handle repetitive tasks like:

- welding

- painting

- assembling components

For example, automotive manufacturers use robotic arms to install parts with accuracy, reducing errors and production time. Collaborative robots (cobots) work alongside humans, improving safety and boosting overall output. The integration of Industry 4.0 technologies connects robotic systems with IoT devices, enabling real-time monitoring and predictive maintenance.

Healthcare and Medicine

Healthcare applies robotics to surgeries, patient care, and laboratory tasks. Surgical robots, such as the Da Vinci system, perform minimally invasive procedures with precision, reducing recovery times. Autonomous robotic systems assist in disinfecting hospitals, delivering medications, and transporting medical supplies, enhancing infection control and operational efficiency. AI-powered robotic assistants aid in diagnosing medical conditions, analyzing medical imagery, and personalizing patient treatment plans.

Retail and Customer Service

Retail and customer service sectors use robots to enhance customer experiences and streamline operations. In stores, robots manage inventory by scanning shelves, restocking items, and assisting customers with finding products. Examples include Lowe’s “LoweBot” and Walmart’s shelf-scanning robots. Automated checkout systems reduce wait times and improve shopping experiences. Chatbots powered by artificial intelligence handle customer inquiries, provide product recommendations, and resolve issues swiftly, improving customer satisfaction and support efficiency.

Transportation and Logistics

Transportation and logistics benefit from automation through improved efficiency and reduced operational costs. Autonomous vehicles, including self-driving trucks and drones, transport goods with greater flexibility and less human intervention. Amazon’s warehouse robots, like Kiva systems, move inventory items quickly and accurately within fulfillment centers. Automated guided vehicles (AGVs) in factories and warehouses streamline internal logistics by moving materials and products efficiently. Advanced fleet management systems leverage robotics and AI to optimize delivery routes and monitor vehicle health in real time.

David Boyd brought valuable insights to News Flip Network, contributing his knowledge in business and technology. His work on streamlining the site’s interface and optimizing backend processes ensured that the platform operates efficiently. Boyd's efforts in integrating advanced tools and managing technical aspects played a significant role in the site's reliable and timely news delivery.

David Boyd brought valuable insights to News Flip Network, contributing his knowledge in business and technology. His work on streamlining the site’s interface and optimizing backend processes ensured that the platform operates efficiently. Boyd's efforts in integrating advanced tools and managing technical aspects played a significant role in the site's reliable and timely news delivery.